Process innovation

Production processes innovation, IoT and AI to increase efficiency

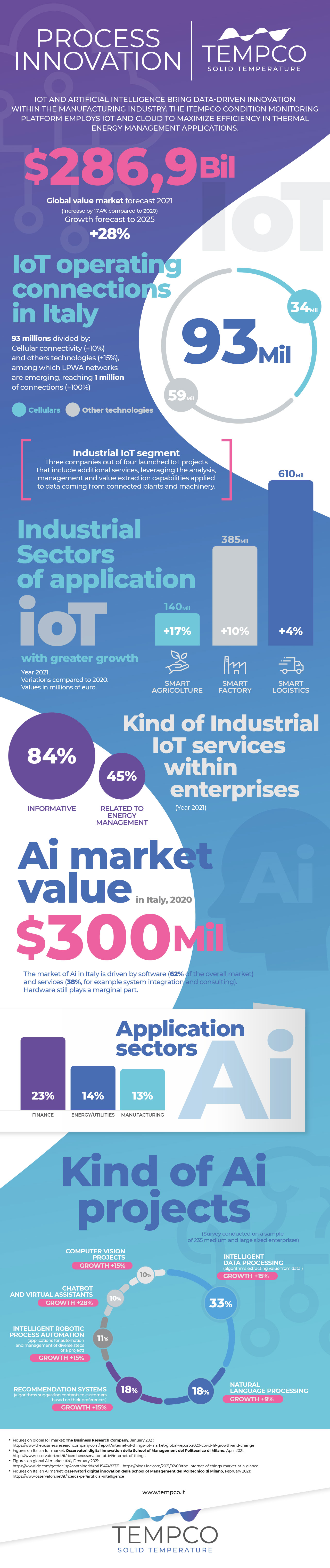

The growing adoption of IoT and Artificial Intelligence solutions within companies in the manufacturing sector is pushing innovation of the process industry toward data-driven models. Connected machines and components ‘talk’ to operators and plant managers, allowing the real time monitoring of the state of production and at the same time of the conditions of manufacturing assets.

Real-time condition monitoring of processes and production systems allows not only to maximize productivity reducing waste and errors, increasing quality using optimization models developed with AI for specific industrial applications. The data science also allows to extend the life cycle of machinery and equipments, enabling new predictive maintenance functions to increase plants’ availability and reliability, avoiding expensive production downtimes.

IoT and AI combined provide at last a transparent insight on effective energy consumes of production processes, aiming to a constant real-time improvement of energy efficiency and costs reduction within the process industry. This is also the goal of the iTempco platform, which employs IoT, analytics and cloud to maximize thermal energy efficiency and energy saving in temperature control and thermal energy management applications for production processes of all kind of industrial sectors.

Download infographic

Download infographic