Free cooling or dry cooling selection

Let’s open the section dedicated to the free cooling, or also smart process cooling, with a sort of axiom: the first energy that can be recovered is the one that’s not consumed. The free cooling is indeed an industrial cooling option inspired to energy saving: these are very simple thermal machines, composed by an air heat exchanger in function of radiator combined with a fan, that allow to obtain cold at low cost aimed to closed circuit process fluids thermoregulation. The aim is to avoid or limit as much as possible the use of chillers, which are very much energy consuming, and of evaporative towers as well, very demanding in terms of maintenance and water consumption.

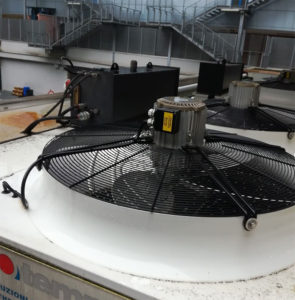

A free cooling system is composed by:

- Finned battery pack

- Copper pipes and aluminum fins

- Housing box/framework in varnished or zinc-coated steel sheet

- Supporting legs

- Air distribution assembly

- Electrical fans

- Electrical connection box

Free coolers offer easy and economic outdoor installation, reliable and flexible operations and highly efficient cooling. Maintenance costs are very low, requiring only a planned cleaning of exchange packs using compressed air or water. Energy consumption is also very much limited, approx. 1/8 in comparison to a chiller. Usually, the finned pack is firmly coupled with the outer steel shell, except in case of very high excursion between ambient air and the temperature of the fluid to be cooled, which is better suited by a floating tubes bundle. This is mounted on support brackets that allow it to move, offering copper tubes a free area in case of thermal expansion or contraction, avoiding the risk of unwanted breakage of pipes near the connections with the housing, that lead to production downtimes and high repair costs.

WEATHER CONDITIONS AND INSTALLATION LOCATION

Similarly to what happens with evaporative towers, free coolers performances are as well very much affected by the ambient air conditions. The employ of a free cooling will thus be very much advantageous in case of an installation in cool environments, where the temperature’s trend throughout the whole year permits to use it for a prolonged time, while leaving energy-consuming chillers in stand-by. In this kind of conditions, free coolers are of course the best solution to achieve high energy efficiency, where cooling temperatures required are not too low. While selecting and installing a free cooling system, the installation site must be carefully evaluated during the engineering phase, in order to properly define project’s ambient temperature and the possible de-rating of the free cooler due to air density, which directly decreases with the increase of the altitude of the installation site, therefore requiring an altitude correction assessment.

Back to index

Back to index Download the complete book

Download the complete book